How to Choose the Right Wear Parts for Cone Crusher?

Jun 06, 2025Cone crushers play a vital role in industries like mining, construction, and aggregates processing. Selecting the right wear parts is essential for optimizing operational costs, extending machine life, and ensuring high-quality output. Here are some key points to help you make the right choice.

Cone crusher wear parts, such as the mantle, bowl liner (concave), feed cone, torch ring, and distributor plate, endure continuous impact and abrasion. These components are crucial for the crusher's performance and life.

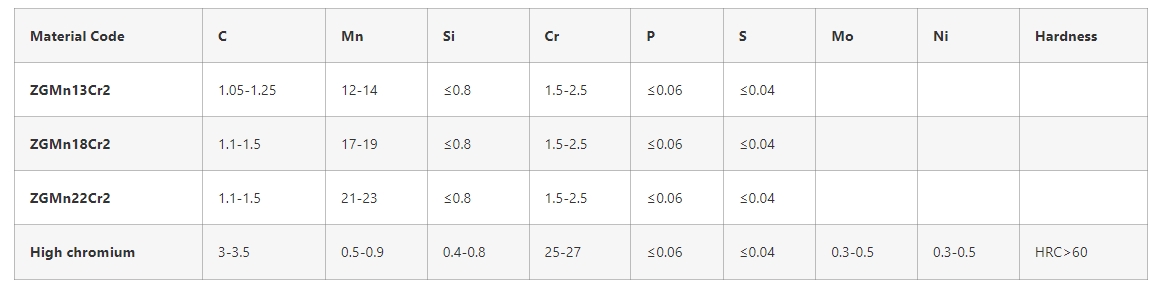

The choice of material significantly impacts durability, efficiency, and cost. Common materials include:

Manganese Steel (Mn13, Mn18, Mn22): High toughness and excellent impact resistance, ideal for medium to hard rock applications.

Alloy Steel: Offers enhanced wear resistance and is suitable for moderate impact applications.

Tungsten Carbide Reinforced Parts: Extremely hard and wear-resistant, best for high-abrasion environments like quartz and iron ore crushing.

Martensitic Steel: Balances impact and wear resistance, suitable for secondary and tertiary crushing.

To maximize productivity and minimize costs, consider the following:

Compatibility: Ensure the wear parts match your crusher’s specifications to avoid efficiency loss and breakdowns.

Rock Type: Hard rocks (granite, basalt) require high-manganese or tungsten carbide parts, while softer materials (limestone, clay) can use standard manganese.

Wear Life and Cost Efficiency: High-quality parts may have a higher upfront cost but offer longer life, reducing downtime and replacement expenses.

Supplier Reputation: Choose suppliers with a strong reputation, high manufacturing standards, and positive reviews. Verify certifications and quality control measures.

Installation Support: Ill-fitting parts can lead to failures. Select suppliers that offer installation guidance and after-sales support.

Proper maintenance extends wear part life and ensures optimal performance:

Regular Inspections: Check for cracks, uneven wear, and material buildup. Replace parts before they fail.

Optimize Settings: Adjust CSS and feed levels to prevent excessive wear. Avoid overloading or underfeeding.

Use the Right Material: Match wear parts to the application. Consider high-performance alloys for extreme conditions.

Proper Lubrication: Keep bearings and moving parts well-lubricated to reduce friction and overheating.

Operator Training: Educate operators on proper feeding techniques and equipment handling.

For high-quality cone crusher wear parts, pls consider Borgers, known for its rich experience, positive reviews, and strong customer support.

Choosing the right cone crusher wear parts is crucial for maximizing efficiency, reducing downtime, and lowering costs. Consider material quality, crusher compatibility, application needs, and supplier reputation. Proper maintenance and regular inspections will further extend the lifespan of your components, ensuring consistent output and cost savings over time.

For more information about Borgers' cone crusher wear parts and services, please visit our official website or contact Borgers service team.